R & D Center

Shanghai shenyuan high temperature line co., LTD. Technology research and development center was established in July 2010, the main research and development field and direction is: using high and new technology to transform traditional industries, with more than 15 technical research and development personnel.

Research and development center on the basis of existing research results, closely track industry advanced technology inside and outside China. We will vigorously develop industrial supporting technologies marked by independent intellectual property rights, carry out extensive technical cooperation, and strive to make breakthroughs in the production technologies of fluoroplastics and silicon rubber cables and new energy cables. At the same time, the research and development center actively carries out technical exchanges and cooperation, improves itself and serves others in the exchange and cooperation, and makes contributions to improve the overall technical level of China's cable industry.

Research and development centre based on independent innovation, in order to serve the company's survival and development as the keynote, practical, pioneering and innovative, in order to enhance the market competitiveness of the company to provide strong technical support. In recent years, according to the market demand, has developed more than 30 new products. According to the research results of the subject and its application in practice, actively carry out the declaration of intellectual property rights.

After nearly 6 years of research and development, the company has become mature for conventional high-temperature resistance cables. The company's next step is to develop new energy - saving and environmentally friendly cables. The company intends to gradually increase the r&d investment in this field in the next few years, laying a solid foundation for the company to smoothly transform and enter unconventional market as soon as possible.

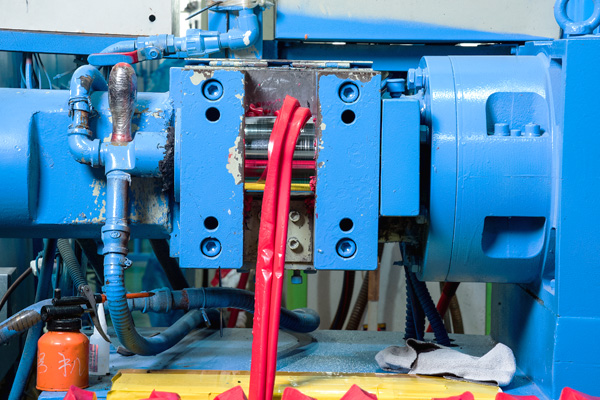

Manufacturing equipment

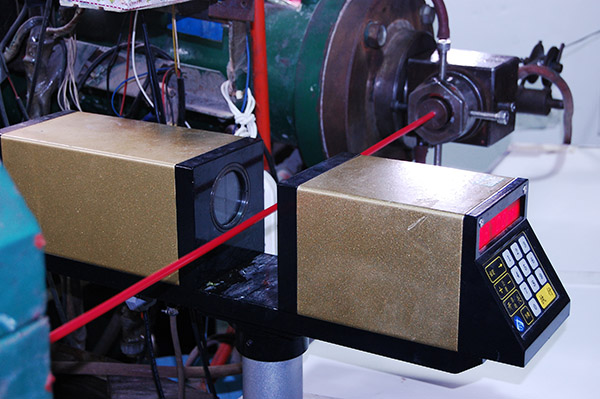

Testing equipment